below is original thread link

https://handletteringforum.com/forum ... f=2&t=3220

now what I have done so far..

sinse clearing does dull the finish(of graphite over glossy 2k urethane paint, Uncleared pieces can look even nicer than real chrome but are too dark to pass for chrome), I tried to Chrome Plate the plastic spoons(using graphite, nothing else)

Here on a 800 gallon nickel plating tank

here when I pulled the plastic spoon to show you it was being plated

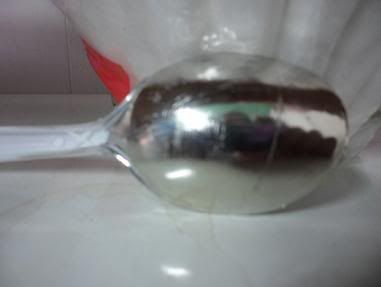

here the finished product(is not the same spoon as you see in above pics, that one had a black background, this one has a white background and it was also chrome plated after the nickel)

here is the plastic spoon with nickel Only

what I can tell from this experience is, I need to sensitize the piece before nickel plating because its like when you silver a mirror without a sensitizer, the nickel is kinda loose, in some parts is strongly attached and in others is kinda loose, I´ll try a stanous chloride sensitizer. I can´t copper plated sinse here in Nicaragua we just don´t use copper plate at all, maybe a home made copper sulfate formula? I´ll keep you guys posted with progress

Thanks

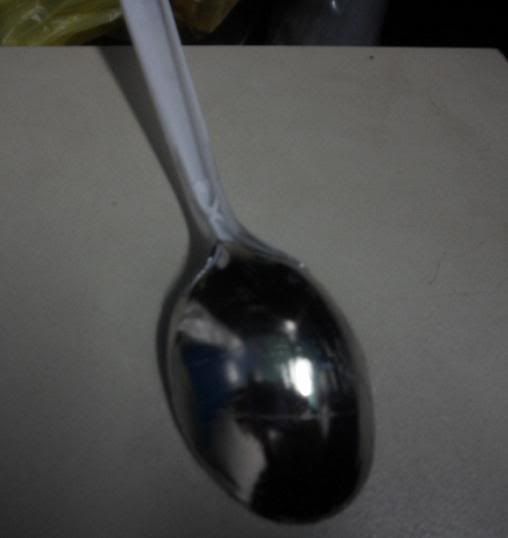

Ok guys I nickel plated a spoon, this time with a rough surface, it not as nice as the one with a shiny surface but its holding very well..

you can see where is the copper wire was holding the spoon. I believe this are the first pics of plating over graphite powder. I believe I can achieve better results I just need to figure out a few more things. I´ll be making a "How To" Video, this method could be use with a Plug and Plate kit for a cheap way to plate small plastic parts at home.

thanks

Marvin

Denver Chapter of the Letterheads

Denver Chapter of the Letterheads