The sign was done using water gilded copper leaf in reverse on glass. The outlines were laid on first in oil-based enamel (one-shot equivalent). The letter infill was then water gilded in copper leaf with gelatin water size made up slightly stronger than for gold leaf work. It was subsequently backed up with oil-based backing paint followed by a coat of clear oil-based varnish.

The sign is located in a café in an air-conditioned building in a coastal sub-tropical location.

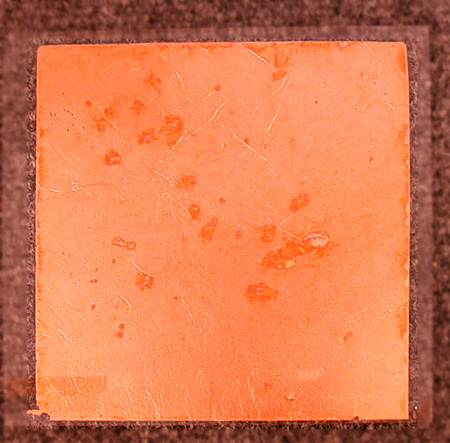

The copper was bright salmon pink (typical of new copper) when it was done in mid 2005. It has now darkened slightly and is developing a patina of other color.

I would like some comments from people experienced in using copper leaf in this way, especially if you have seen this occur before. Please include comments that respond to the clients concerns of:

What is causing it?

Would this normally be expected to occur; and if so, within what timeframe?

What will be the long term result and how long will the sign last before needing to be replaced?

Original photo taken in June 2005

Recent photos

Denver Chapter of the Letterheads

Denver Chapter of the Letterheads