Welcome to The Hand Lettering Forum!

This is an interactive Bulletin Board on the topics of Sign making, design, fabrication, History, old Books and of coarse Letterheads, Keepers of the craft. The Hand Lettering Forum features links to resources, sign art history, techniques, and artists profiles. Learn more about Letterheads at https://theletterheads.com. Below you'll see Mchat has been added as a live communication portal for trial, and the Main forum Links are listed below.

This is an interactive Bulletin Board on the topics of Sign making, design, fabrication, History, old Books and of coarse Letterheads, Keepers of the craft. The Hand Lettering Forum features links to resources, sign art history, techniques, and artists profiles. Learn more about Letterheads at https://theletterheads.com. Below you'll see Mchat has been added as a live communication portal for trial, and the Main forum Links are listed below.

Glue, continued

Moderators: Ron Percell, Mike Jackson, Danny Baronian

-

Danny Baronian

- Site Admin

- Posts: 638

- Joined: Wed Apr 07, 2004 2:16 am

- Contact:

Glue, continued

In January Doug posted his results of testing various glues used to glue up HDU.

I'd like to know what other types of glue others are using on their projects, and why.

Doug and Joe find polyurethane glue (Gorilla glue is one brand name) - to be the best. I've found the same to be true, with exceptions and a warning.

Polyurethane glues aren't all equal. I did a project years ago that was made from recycled newspaper and milk cartons. The manufacture specified Gorilla glue, probably because it was the only one on the market at the time. Following that job, in need of more glue I purchased a generic brand from Home Depot. The results of those tests for HDU and wood using generic polyurethane glue was similar to Gorilla glue.

Any adhesive, like paints and other products, have a shelf life. After 6 months the home depot brand had reached or exceeded it's shelf life, and produced an inferior bond so it was replaced with Gorilla glue. That glue was purchased over a year ago, and still performs well.

While Gorilla glue is considerably more expensive, it has a better shelf life, and provides a better bond from what I've found.

Has anyone tried Joe's method of gluing up panels? If you haven't you should:

https://handletteringforum.com/forum ... f=2&t=2353

It didn't make sense, since the objective is to keep the glue off the surface, Joe's method seemed to spread it out more. After trying it, the results were exactly as Joe described. The glue beaded up and were removed with a putty knife leaving no residue on that face at all.

How'd you figure that one out Joe? Works beautifully!

I'd like to know what other types of glue others are using on their projects, and why.

Doug and Joe find polyurethane glue (Gorilla glue is one brand name) - to be the best. I've found the same to be true, with exceptions and a warning.

Polyurethane glues aren't all equal. I did a project years ago that was made from recycled newspaper and milk cartons. The manufacture specified Gorilla glue, probably because it was the only one on the market at the time. Following that job, in need of more glue I purchased a generic brand from Home Depot. The results of those tests for HDU and wood using generic polyurethane glue was similar to Gorilla glue.

Any adhesive, like paints and other products, have a shelf life. After 6 months the home depot brand had reached or exceeded it's shelf life, and produced an inferior bond so it was replaced with Gorilla glue. That glue was purchased over a year ago, and still performs well.

While Gorilla glue is considerably more expensive, it has a better shelf life, and provides a better bond from what I've found.

Has anyone tried Joe's method of gluing up panels? If you haven't you should:

https://handletteringforum.com/forum ... f=2&t=2353

It didn't make sense, since the objective is to keep the glue off the surface, Joe's method seemed to spread it out more. After trying it, the results were exactly as Joe described. The glue beaded up and were removed with a putty knife leaving no residue on that face at all.

How'd you figure that one out Joe? Works beautifully!

-

joe cieslowski

- Posts: 338

- Joined: Sun Apr 11, 2004 6:15 pm

- Location: east canaan ct

- Contact:

Re: Glue, continued

Danny,

How did I figure that out?

I always say that the blessing of age (or is it a curse?) is you have more perspective. (experience?)

I was taught in college that glues by themselves have no strength. Glue is a bonding agent used to adhear two pieces of material together. The less glue between the two pieces the better the bond. (Glue manufacturers would loose 30% of their overall sales if every woodworker used this glue up method! )

)

Next.......urethane glue is URETHANE which is activated by moisture. If you don't add water, it will combine with the moisture in the air or the substraight to cure. HDU IS urethane too. Good match!!!!

Good match!!!!

Straight out of the bottle, it cures very hard (read dense). The more moisture that is added, the less dense it becomes. HDU isn't very dense........soooooo, even tho I use a lot of water in the process, the resulting material (the glue) is closer to the actual density of the HDU, which as stated above leaves less glue (remember, glue has no strength by itself) between your two pieces.

Result? Fast set times. Easy clean up. When sanded afterward, no glue line (cause the glue isn't harder than the HDU at the joint.) AND you use less of that expensive glue. Win, win, win!

Orrrrrrrrrrrrrrrrrrrrr, forget everything I just said and read the directions. "Apply sparringly to one piece and wet the opposite piece with water" Duhhhhhhhhh (That's how I really figured it out.....lol)

(That's how I really figured it out.....lol)

AND, the description of the glue says that it fills gaps......hmmmm, must be expanding.

Actually, there's more but it would be just redundant.

Curse lifted??

Joe

How did I figure that out?

I always say that the blessing of age (or is it a curse?) is you have more perspective. (experience?)

I was taught in college that glues by themselves have no strength. Glue is a bonding agent used to adhear two pieces of material together. The less glue between the two pieces the better the bond. (Glue manufacturers would loose 30% of their overall sales if every woodworker used this glue up method!

Next.......urethane glue is URETHANE which is activated by moisture. If you don't add water, it will combine with the moisture in the air or the substraight to cure. HDU IS urethane too.

Straight out of the bottle, it cures very hard (read dense). The more moisture that is added, the less dense it becomes. HDU isn't very dense........soooooo, even tho I use a lot of water in the process, the resulting material (the glue) is closer to the actual density of the HDU, which as stated above leaves less glue (remember, glue has no strength by itself) between your two pieces.

Result? Fast set times. Easy clean up. When sanded afterward, no glue line (cause the glue isn't harder than the HDU at the joint.) AND you use less of that expensive glue. Win, win, win!

Orrrrrrrrrrrrrrrrrrrrr, forget everything I just said and read the directions. "Apply sparringly to one piece and wet the opposite piece with water" Duhhhhhhhhh

AND, the description of the glue says that it fills gaps......hmmmm, must be expanding.

Actually, there's more but it would be just redundant.

Curse lifted??

Joe

Makin Chip$ and Havin Fun!

-

joe cieslowski

- Posts: 338

- Joined: Sun Apr 11, 2004 6:15 pm

- Location: east canaan ct

- Contact:

Re: Glue, continued

I also agree that all PU glues are not created equal. Just like HDU, the less urethane in it = less cost. Cheap PU glues have more filler....less urethane.

Shelf life...... True! They all have a shelf life, but the denser ones last longer (read more expensive).

Now, I'm going to express a personal opinion (I have no real proof). Big box stores, press manufacturers on price (pretty common knowledge), sooooooo, the manufacturers sell em old stock which doesn't have as much viaibility as new stock. Because the "off brands" don't sell quickly and have a shorter life span to begin with, the stuff you bought shot it's load pretty quickley. I've found this to be true with other products too......coatings, tape etc.

The soap box is now yours....

Joe

Shelf life...... True! They all have a shelf life, but the denser ones last longer (read more expensive).

Now, I'm going to express a personal opinion (I have no real proof). Big box stores, press manufacturers on price (pretty common knowledge), sooooooo, the manufacturers sell em old stock which doesn't have as much viaibility as new stock. Because the "off brands" don't sell quickly and have a shorter life span to begin with, the stuff you bought shot it's load pretty quickley. I've found this to be true with other products too......coatings, tape etc.

The soap box is now yours....

Joe

Makin Chip$ and Havin Fun!

-

Danny Baronian

- Site Admin

- Posts: 638

- Joined: Wed Apr 07, 2004 2:16 am

- Contact:

Re: Glue, continued

Curse lifted, on the glue, on you? Didn't know there was one.

Thanks for the explanation, makes sense now, but I wouldn't have thought that the foam would be less dense, therfore making for easier clean up. want it.

I used to spend so much time masking off areas I didn't want glue to go - or expand on to, because once it got there it was a bear to clean up.It still got where you didn't

Never thought about the application either, follow the directions which say to cover the part completely with an even coat of glue, spray the other w/ water. The result was glue ozzing out of the joints. Made some brackets yesterday of 4/4 stock into a mating dado. Small, less than 1/8" bead down the center, sprayed water on the opposing part, resulting with a joint as you described.

Expand? I glued up a job a few yeas ago, 3/4" 4' x 8' marine ply to 3" HDU. Covered the whole board about 3/32" thick glue and clamped up with every clamp in the shop and weighted down the center with 6 eleveator weights - 50 lbs each. Ended up with a bow in the center where the glue expanded 5/8"!

After that it was always less is more (or better)!

What I'd like to know is why you kept it a secret so long.

Danny

Thanks for the explanation, makes sense now, but I wouldn't have thought that the foam would be less dense, therfore making for easier clean up. want it.

I used to spend so much time masking off areas I didn't want glue to go - or expand on to, because once it got there it was a bear to clean up.It still got where you didn't

Never thought about the application either, follow the directions which say to cover the part completely with an even coat of glue, spray the other w/ water. The result was glue ozzing out of the joints. Made some brackets yesterday of 4/4 stock into a mating dado. Small, less than 1/8" bead down the center, sprayed water on the opposing part, resulting with a joint as you described.

Expand? I glued up a job a few yeas ago, 3/4" 4' x 8' marine ply to 3" HDU. Covered the whole board about 3/32" thick glue and clamped up with every clamp in the shop and weighted down the center with 6 eleveator weights - 50 lbs each. Ended up with a bow in the center where the glue expanded 5/8"!

After that it was always less is more (or better)!

What I'd like to know is why you kept it a secret so long.

Danny

-

joe cieslowski

- Posts: 338

- Joined: Sun Apr 11, 2004 6:15 pm

- Location: east canaan ct

- Contact:

Re: Glue, continued

Well, i just spent a half hour on a reply but the computter gods logged me off before I could post it. It was mostly balony anyway.

The curse was in my refrence to age....."blessing or curse".

Keeping secrets?.......ME?

I just throw it out there when I get an opening.....like sharpening and laminating wood panels.

I'm just happy that somebody got somethig usefull outa my ramblings.

BTW, Danny......that little sample I sent you about 4 years ago......it should have exploded by now?

There is still time to book into the "Brush and Blade Express".......BDL airport.....I'll pic you up...

All my secrets will be revealed!!!!!! lol

Joe

The curse was in my refrence to age....."blessing or curse".

Keeping secrets?.......ME?

I just throw it out there when I get an opening.....like sharpening and laminating wood panels.

I'm just happy that somebody got somethig usefull outa my ramblings.

BTW, Danny......that little sample I sent you about 4 years ago......it should have exploded by now?

There is still time to book into the "Brush and Blade Express".......BDL airport.....I'll pic you up...

All my secrets will be revealed!!!!!! lol

Joe

Last edited by joe cieslowski on Tue Apr 07, 2009 2:20 pm, edited 1 time in total.

Makin Chip$ and Havin Fun!

-

Danny Baronian

- Site Admin

- Posts: 638

- Joined: Wed Apr 07, 2004 2:16 am

- Contact:

Re: Glue, continued

That little sample? So you expected it to explode?

I'll be kind and send you a picture, not post one.

What is the longest exterior sign you've made that's weathered well?

The first to go is the clear coat, followed by incised carving through paint masks then painted or gilded. It's hanging on a North facing wall on my shop. The clear is gone except for the bottom cove and edge, that looks just like the day it was made, as well as the cast, gilded Fleur De Les.

The mask method is great, but not on or with all materials. When you have a mask, carve, paint and gild you have an area a few thousands of an inch that is very fragile - the space that the mask takes up. The clear coat will protect it until it starts to break down, so you have clear failure first followed by lifting of whatever incised work you've done.

You can feel those areas even after a clear coat. Run you finger over incised areas and you can feel the ridge left by the mask.

I'd love to come back to your get together, along with a few more going on back east over the next few months, but my wife says I gotta stay put for right now.

I'll have to make do with the pictures you take and post here!

Danny

I'll be kind and send you a picture, not post one.

What is the longest exterior sign you've made that's weathered well?

The first to go is the clear coat, followed by incised carving through paint masks then painted or gilded. It's hanging on a North facing wall on my shop. The clear is gone except for the bottom cove and edge, that looks just like the day it was made, as well as the cast, gilded Fleur De Les.

The mask method is great, but not on or with all materials. When you have a mask, carve, paint and gild you have an area a few thousands of an inch that is very fragile - the space that the mask takes up. The clear coat will protect it until it starts to break down, so you have clear failure first followed by lifting of whatever incised work you've done.

You can feel those areas even after a clear coat. Run you finger over incised areas and you can feel the ridge left by the mask.

I'd love to come back to your get together, along with a few more going on back east over the next few months, but my wife says I gotta stay put for right now.

I'll have to make do with the pictures you take and post here!

Danny

-

joe cieslowski

- Posts: 338

- Joined: Sun Apr 11, 2004 6:15 pm

- Location: east canaan ct

- Contact:

Re: Glue, continued

First,

I'm glad I sent out those samples......I learned a lot. I now apply 5 coats insted of 3. I also now seal all the edges where I've cut throught the mask and add an extra coating across the top. They still require recoating on a regular basis but the window is a bit larger now. Thanks for helping me out on this one.

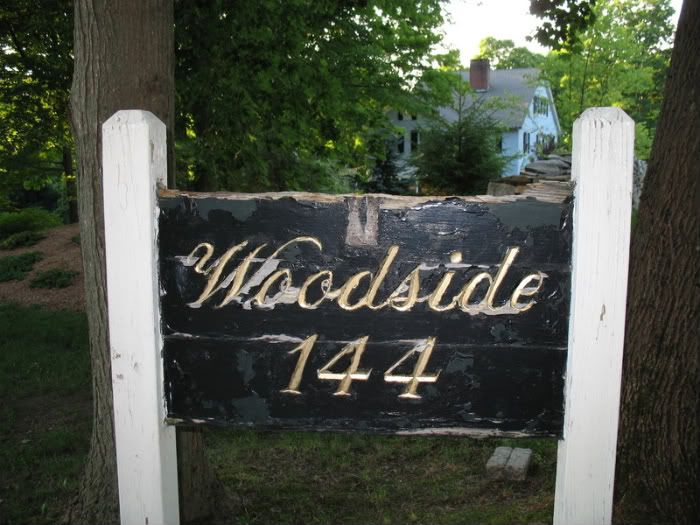

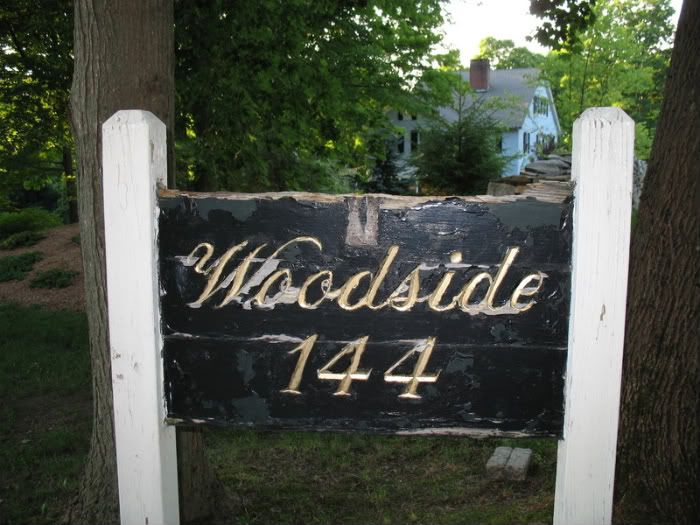

Here's one I did 30 years ago......it's just up the street from me.

How do you like the Speedball lettering font?

Now, I hope you are sitting down........I used Minwax wood stains on it......that's all. It is shaded during the summer, so that helps but I can't believe it is still working.

Here's on that one might use as a poster child for NOT using pine....

It used to have a clump of birch trees top center.....25+ years.....zero maintance.....still works!!!! Sorry, but good enough for me.

BTW, this sign faces south, full sun......you are looking at the pith side of each board.....pretty flat huh?

Thanks for your help with the sample.....I think I already know what the pic is gonna look like.

I'll get some pics up after the meet......wooda been nice to meet you.....next time!

Joe

I'm glad I sent out those samples......I learned a lot. I now apply 5 coats insted of 3. I also now seal all the edges where I've cut throught the mask and add an extra coating across the top. They still require recoating on a regular basis but the window is a bit larger now. Thanks for helping me out on this one.

Here's one I did 30 years ago......it's just up the street from me.

How do you like the Speedball lettering font?

Now, I hope you are sitting down........I used Minwax wood stains on it......that's all. It is shaded during the summer, so that helps but I can't believe it is still working.

Here's on that one might use as a poster child for NOT using pine....

It used to have a clump of birch trees top center.....25+ years.....zero maintance.....still works!!!! Sorry, but good enough for me.

BTW, this sign faces south, full sun......you are looking at the pith side of each board.....pretty flat huh?

Thanks for your help with the sample.....I think I already know what the pic is gonna look like.

I'll get some pics up after the meet......wooda been nice to meet you.....next time!

Joe

Makin Chip$ and Havin Fun!

-

Doug Bernhardt

- Posts: 1077

- Joined: Fri Apr 09, 2004 9:29 am

- Location: Ottawa Canada

- Contact:

Re: Glue, continued

Yeo Guys, Just to step back a bit........I tested the PeeYou (PU) glue against the contractors construction adhesive PL Premium (as well as many others) and was most satisfied with the PL with foam to plywood although the PU was just as good when attaching foam to foam. Both required a huge amount of chisel and hammer whacks to get them to separate.......... Isn't it satisfying to see an old sign in such good repair? One of my first...if not the first carved sign I made in the then plentiful redwood is still around and looking just dandy. Natural wood with stain, followed by west system and several coats of spar varnish.

-

joe cieslowski

- Posts: 338

- Joined: Sun Apr 11, 2004 6:15 pm

- Location: east canaan ct

- Contact:

Denver Chapter of the Letterheads

Denver Chapter of the Letterheads