Pat, thanks for the mayor contribution!

Mike, good to hear from you.

I thought I had the right thickness... It is exactly the thickness I was learnt at the workshop.

Maybe my photo's are not very well taken. The size of the glass is only 5 x 5 inch, the complete scroll 4 inch high!

I think normally one would mica etch these tiny detailed scrolls, but I wanted to see what the minimum size for glue chipping would be.

And I never worked with the asphaltum method, so I thought in combining those wishes in these experiments.

So if I am correct in interpreting your good points, maybe it is the extreme small scale of the photo's and ornaments which shows these 'thick' glue blobs and round edges.

Here a few follow up photo's of the experiments that were up and running:

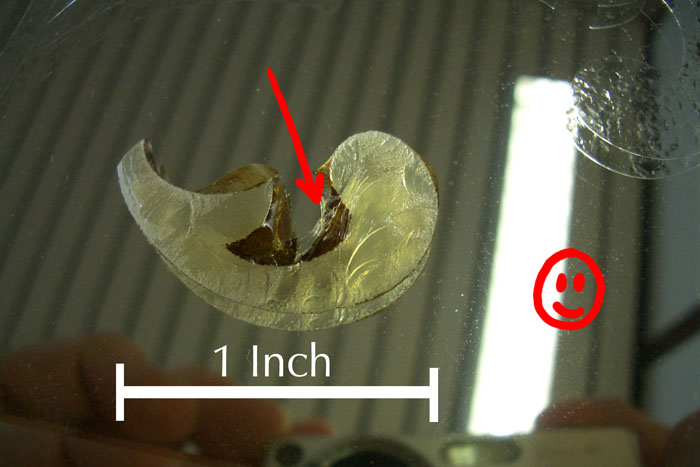

Here a 1 inch chip from the bitumen sample.

Note that the red outline shows how the glass was chipped along with the bitumen wich was on the glass outside the sandblasted surface.

Conclusion: Not perfectly water/glue repelent for extreme small detail chipping without cutting.

- Bitumen.JPG (73.85 KiB) Viewed 43511 times

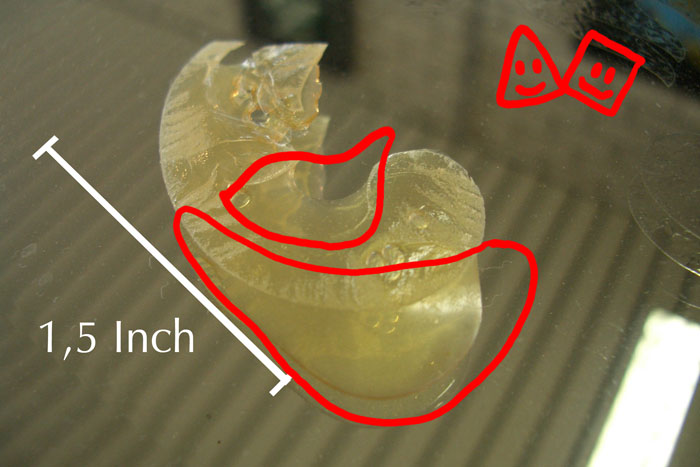

Here a 1,5 inch chip from the clear waterrepelent wall protector.

Note that the red outlines show how the glue chipped the glass, but absolutely did not attack the non-sandblasted parts which were still coated with the magic stuff.

Conclusion: Looks like the perfect water/glue repelent for extreme small detail chipping without cutting.

- Waterrepelent clear.JPG (77.45 KiB) Viewed 43513 times

All comments are greatly appreciated!

Closing the doors for three days and off to Euro Disney Paris.

Erik

Denver Chapter of the Letterheads

Denver Chapter of the Letterheads