My experience in carving letters is limited, so I have a question related to that.

I'm having a vendor cut out some 1" thick HDU letters for me on their CNC router. They will also router a prismatic face on the letters. I will then clean up the crotches to make it appear hand-carved and other detail to correct the machined look and then I'm going to gild them with 23kt gold leaf.

What I'm wondering is if there is a rule of thumb ratio that you use to determine the shoulder on the letter. How deep should I ask them to cut the prismatic portion?

Most of these letters are 7-3/4" high. Of course, it is a thick & thin letter style so the strokes vary somewhat: the verticals are approximately 1-1/8" wide while the horizontal strokes are just under 1/2". I'm thinking of about 1/4" depth but I wanted to see what some of the expert carvers like Doug & Joe or anyone else would recommend.

Of course others, like Danny, who probably deal with this all the time on your router may be able to give more pertinent advice. Is the determining factor the depth or, I assume, the angle of the bit? Or both? Having never operated a CNC router either, I'm kind of in the dark here. But what I'm after is trying to have a nice carved face that isn't too severe and displays the gold leaf nicely.

Welcome to The Hand Lettering Forum!

This is an interactive Bulletin Board on the topics of Sign making, design, fabrication, History, old Books and of coarse Letterheads, Keepers of the craft. The Hand Lettering Forum features links to resources, sign art history, techniques, and artists profiles. Learn more about Letterheads at https://theletterheads.com. Below you'll see Mchat has been added as a live communication portal for trial, and the Main forum Links are listed below.

This is an interactive Bulletin Board on the topics of Sign making, design, fabrication, History, old Books and of coarse Letterheads, Keepers of the craft. The Hand Lettering Forum features links to resources, sign art history, techniques, and artists profiles. Learn more about Letterheads at https://theletterheads.com. Below you'll see Mchat has been added as a live communication portal for trial, and the Main forum Links are listed below.

Prismatic Letters

Moderators: Ron Percell, Mike Jackson, Danny Baronian

-

Mike Jackson

- Site Admin

- Posts: 1705

- Joined: Tue Apr 06, 2004 11:02 pm

- Location: Jackson Hole, WY

- Contact:

Dan,

Actually, you tell them to use the most shallow V bit they have. After that, it is purely mathematics as to how deep it carves to the edge based on the thickness of the widest stroke. It has been over 13 years since I used our old CNC router, so I don't remember the angle on our most shallow bit.

M. Jackson

Actually, you tell them to use the most shallow V bit they have. After that, it is purely mathematics as to how deep it carves to the edge based on the thickness of the widest stroke. It has been over 13 years since I used our old CNC router, so I don't remember the angle on our most shallow bit.

M. Jackson

Mike Jackson / co-administrator

Golden Era Studios

Vintage Ornamental Clip art

Jackson Hole, WY

Photography site:

Teton Images

Jackson Hole photography blog:

Best of the Tetons

Golden Era Studios

Vintage Ornamental Clip art

Jackson Hole, WY

Photography site:

Teton Images

Jackson Hole photography blog:

Best of the Tetons

-

joe cieslowski

- Posts: 338

- Joined: Sun Apr 11, 2004 6:15 pm

- Location: east canaan ct

- Contact:

OK,

I'll stick my neck out here.

First, the angle of the bit will determine the height of the shoulder. Most folks go for a shallow bit.....I believe 120 degrees.

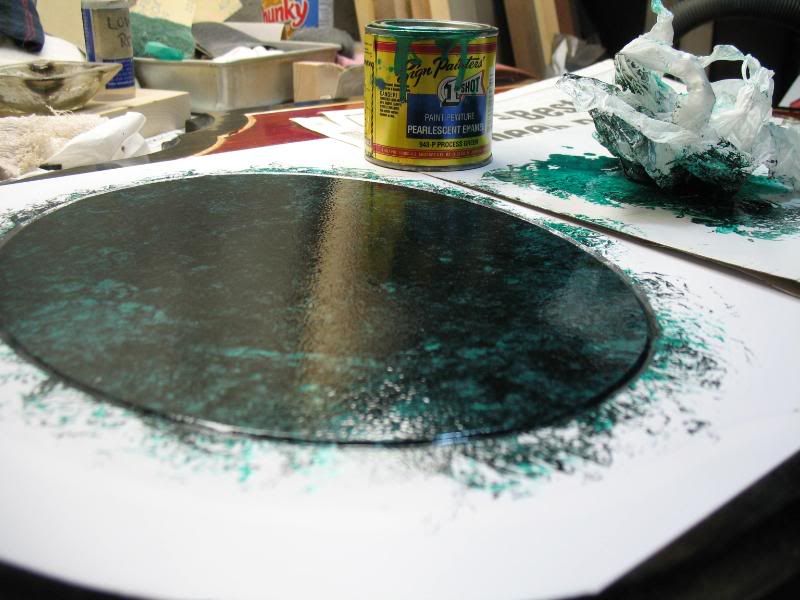

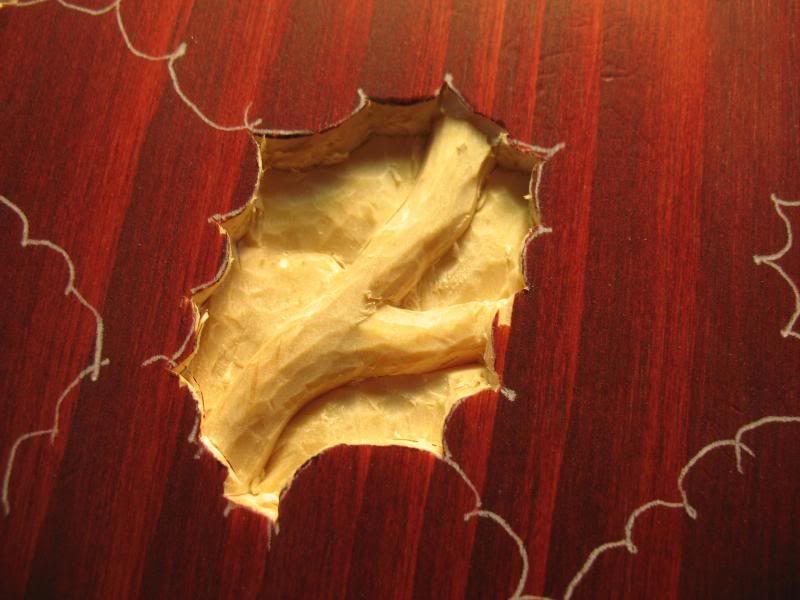

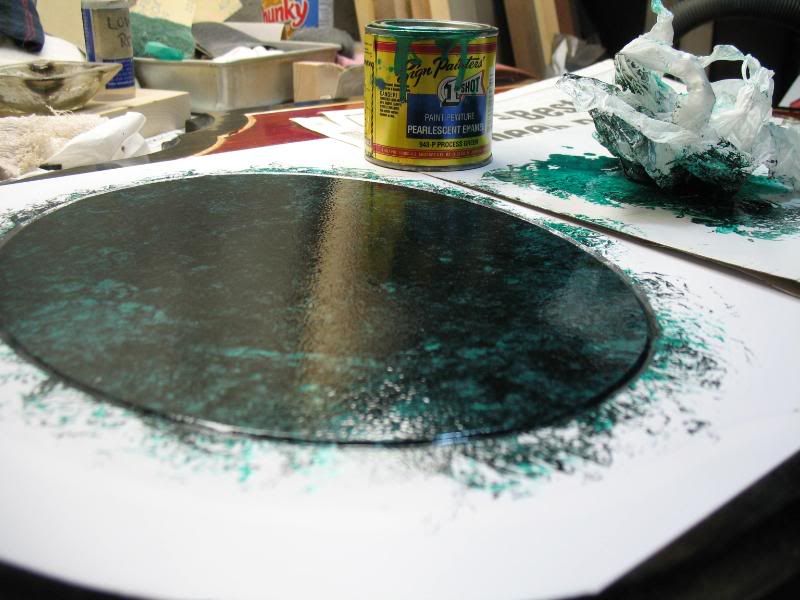

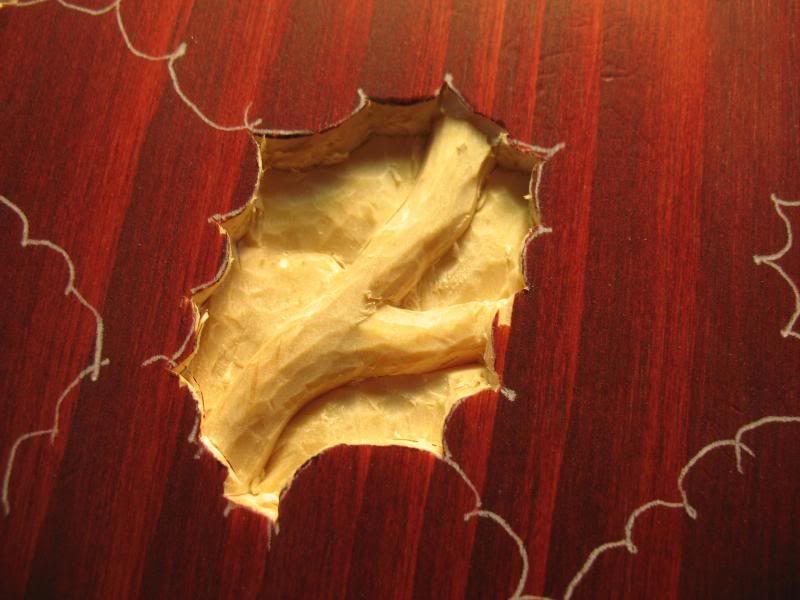

Next, depending on the degree of difference between the thick and thin elements of your font, the distortion can be extreme (IMO). More if there is a big difference.....less if they are closer to the same. I really don't think you will be able to "clean up" the crotches to make them look right. It's just the way it is. Here are a couple of 9 inchers I just did.......these would look real bad as prismatics off a router...

If you don't have a lot of letters, it really isn't that difficult to sculpt them yourself. At French Kiss A Brush, Nancy and Noella had a whole crowd sculpting prismatic letters for a sign that that they made at the meet. I'm using the term sculpt because I was the only one using carving tools.....they were all using files, sureforms and sand paper.....thet all came out looking really good.

If you decide to go this route, I would have the letters cut out on the router, but not the full depth.........say about 7/8"deep. This will make it easier to hold onto. When you are done, just set up a verticle fence on your band saw and slice off the extra material. This is how we did it for the FKAB logo.....

Just my 2 cents.

Good Luck,

Joe

I'll stick my neck out here.

First, the angle of the bit will determine the height of the shoulder. Most folks go for a shallow bit.....I believe 120 degrees.

Next, depending on the degree of difference between the thick and thin elements of your font, the distortion can be extreme (IMO). More if there is a big difference.....less if they are closer to the same. I really don't think you will be able to "clean up" the crotches to make them look right. It's just the way it is. Here are a couple of 9 inchers I just did.......these would look real bad as prismatics off a router...

If you don't have a lot of letters, it really isn't that difficult to sculpt them yourself. At French Kiss A Brush, Nancy and Noella had a whole crowd sculpting prismatic letters for a sign that that they made at the meet. I'm using the term sculpt because I was the only one using carving tools.....they were all using files, sureforms and sand paper.....thet all came out looking really good.

If you decide to go this route, I would have the letters cut out on the router, but not the full depth.........say about 7/8"deep. This will make it easier to hold onto. When you are done, just set up a verticle fence on your band saw and slice off the extra material. This is how we did it for the FKAB logo.....

Just my 2 cents.

Good Luck,

Joe

Makin Chip$ and Havin Fun!

-

Danny Baronian

- Site Admin

- Posts: 638

- Joined: Wed Apr 07, 2004 2:16 am

- Contact:

Hi Dan,

Incised letters run well, and don't look much different from hand carving, as the bit sharpens the corners properly.

Prismatic is another thing, you cannot get around the weird crotches you get on a router. The software looks at the letter, centerlines it, and routes to the center line. In the process it rounds the crotches.

For most work it's fine, but if you want to get a true hand carved look, you'll have to run a shallow prismatic path, and carve down from there. Use a shallow bit as Mike suggested, preferably 150°.

Sign Business ran an article by someone at Noel's shop that shows how the letters were run at 1/ 4 or 1/2 depth to establish the general shape, and act as a guide. The balance was carved by hand.

Depending on what your're doing and how extensive it is, you can go in and alter each letter prior to running on the router. Take A for example, if the intersections are modified at the cross bar and the top v juncture, the router will run the letter cleaner. While this can be done, it takes some time and adjustments to run right.

Danny

Incised letters run well, and don't look much different from hand carving, as the bit sharpens the corners properly.

Prismatic is another thing, you cannot get around the weird crotches you get on a router. The software looks at the letter, centerlines it, and routes to the center line. In the process it rounds the crotches.

For most work it's fine, but if you want to get a true hand carved look, you'll have to run a shallow prismatic path, and carve down from there. Use a shallow bit as Mike suggested, preferably 150°.

Sign Business ran an article by someone at Noel's shop that shows how the letters were run at 1/ 4 or 1/2 depth to establish the general shape, and act as a guide. The balance was carved by hand.

Depending on what your're doing and how extensive it is, you can go in and alter each letter prior to running on the router. Take A for example, if the intersections are modified at the cross bar and the top v juncture, the router will run the letter cleaner. While this can be done, it takes some time and adjustments to run right.

Danny

-

Doug Bernhardt

- Posts: 1077

- Joined: Fri Apr 09, 2004 9:29 am

- Location: Ottawa Canada

- Contact:

Sounds like a heap of great advice so far. I rarely carve foam although Jesper (in my shop often) does 90% of the foam projects when they need doing. I sort of feel my way to a depth I like and then go from there. Jesper uses ladies nail files (paper ones) that you get at the dollar store as well as a pile of different sanding devises after initial rough out with tools. Unlike wood foam is easy to shape with sandpaper. Good Luck

Denver Chapter of the Letterheads

Denver Chapter of the Letterheads