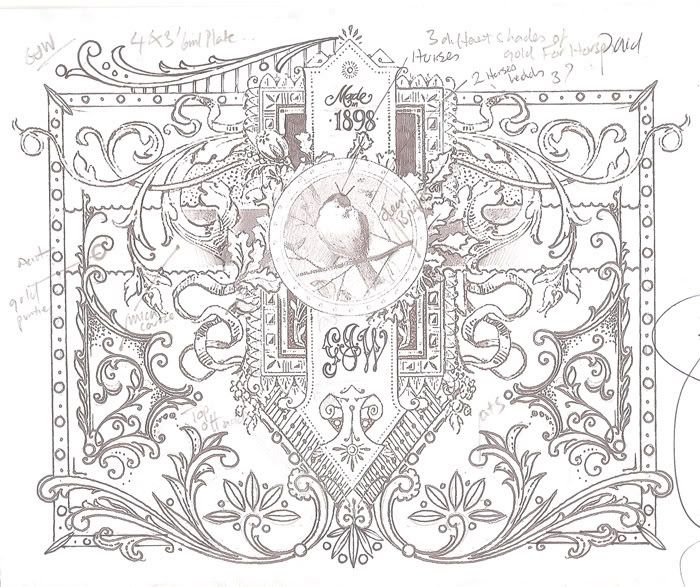

Hand sketched very roughly and the penned over with black ink. The bird illustration was changed as the client prefered horses.

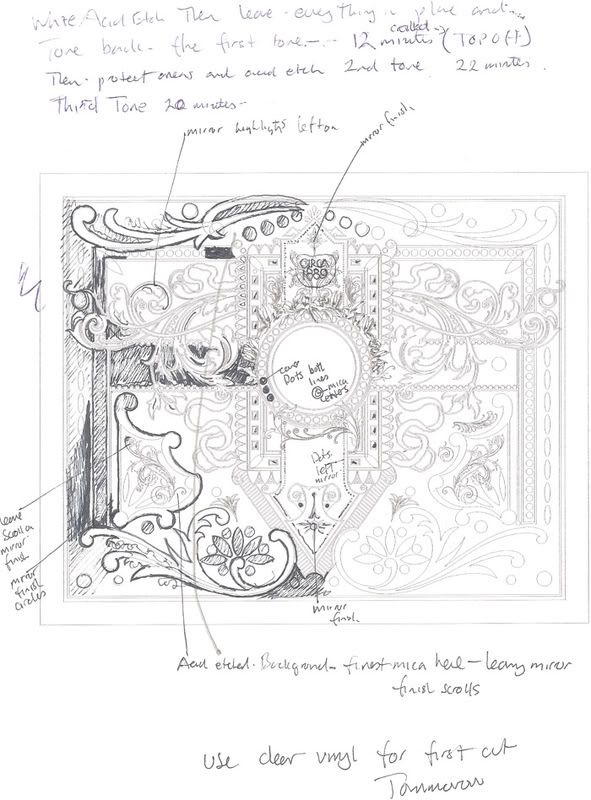

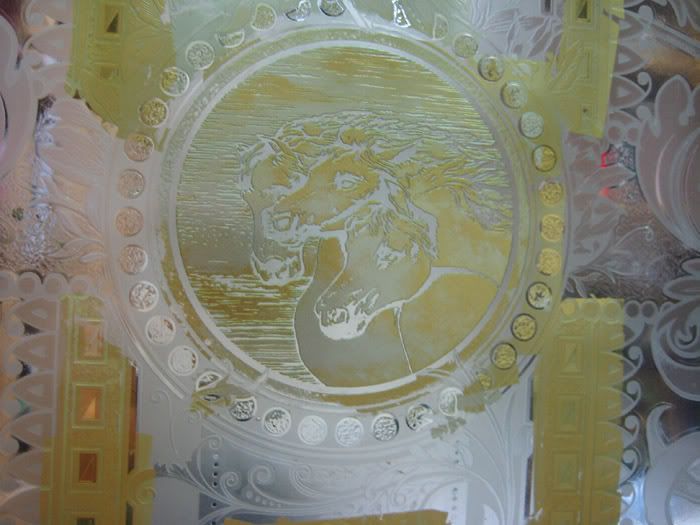

workings out for some of the 6 tones of acid etching. The illustration was hand vectored ready for cutting by plotter.

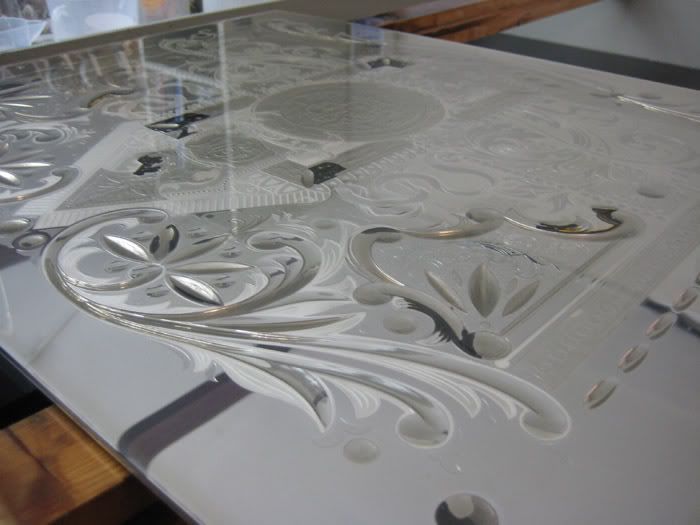

there are a total of 4 panels x2 at 27inches by 22inches x1 at 4ft x 3ft and a smaller panel at 20inches by 17inches.

This is why I vectored the design to speed things up and avoid all the hand cutting plus the computer can cut alott smaller detail and much quicker than me.

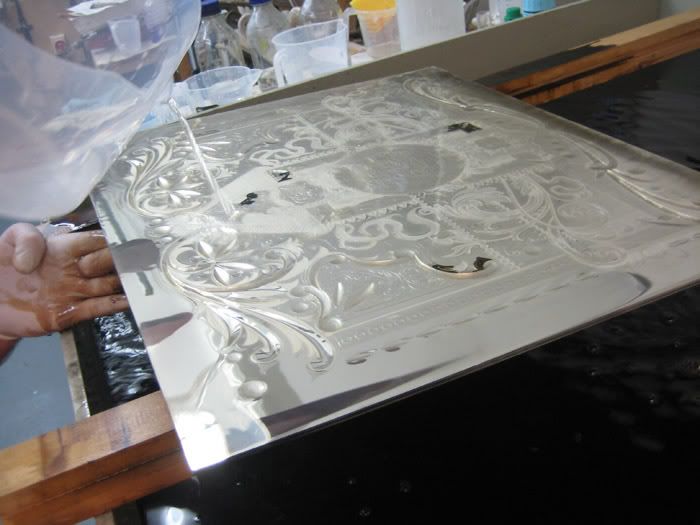

I made a drawing showing me where to start my brilliant cutting ,once the cutting was finished and polished I matched up the areas for acid etching the first white tone

This shows the resist covering the glass cutting and exposing the areas for white acid. a combination of hand cutting and computer was used as it was impossible for

exact positioning of the resist plus it is tradition here to give the brilliant cutting a white acid etched line around the cuts.

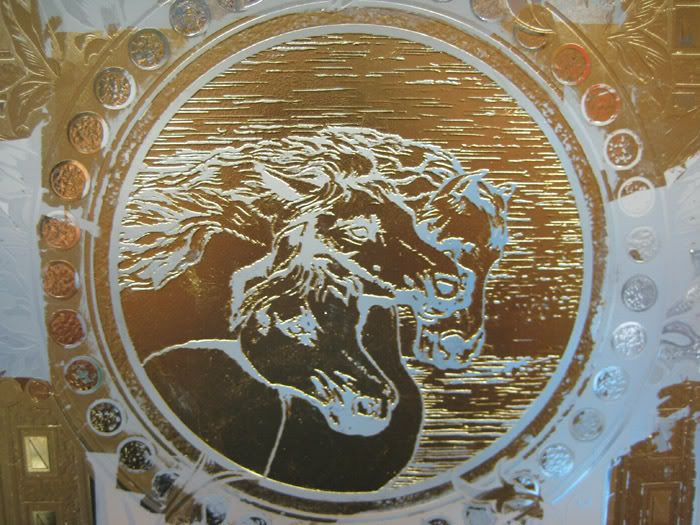

The tone was toped off for 8 minutes ready for the first acid tone. A top off is when the acid is cut back before any work is done. If I silver straight onto the first tone of pure white it would look like dirty sandblasting and not have the correct shade for a silvered panel .A top off effect would not be needed for glass which goes into pub windows which lets light through.

topping off

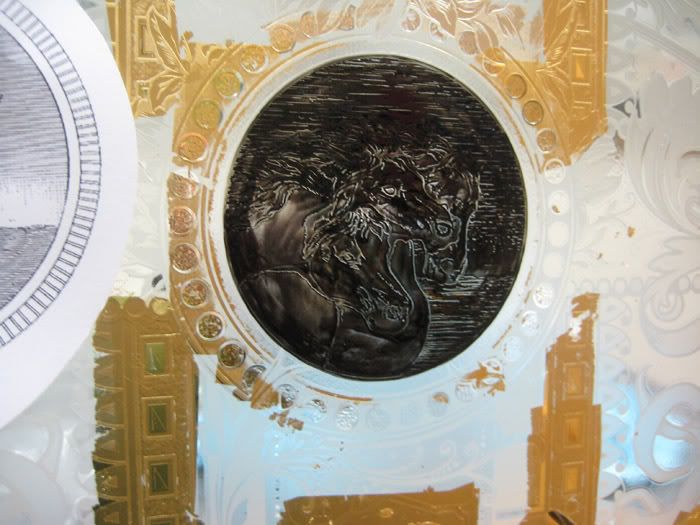

now the second tone is made using a mix of 3-1 for 12 min

I use a light box here and add hand brushed details with acid resist paints

areas recovered and parts removed for acid mica texture.

now I have jumped forward with this shot.The panel is covered with clear vinyl

any areas I choose to etch now would need to be hand cut. On the border you see mica again with a fine small stipple to it.

2 shades

3 shades

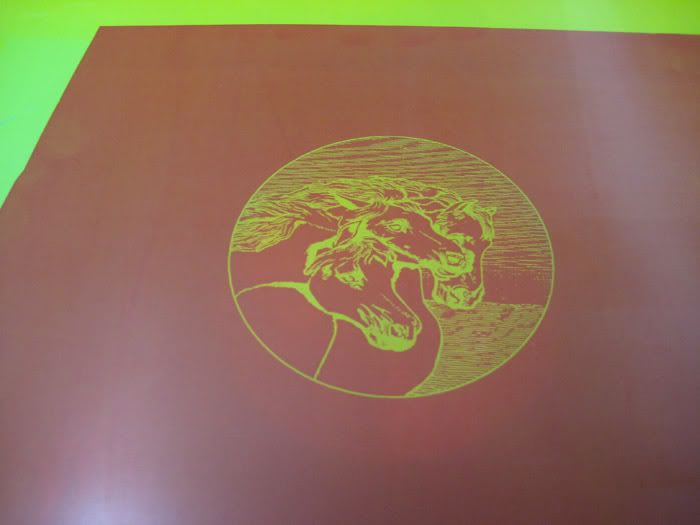

Hand drawn horses and black penned for light exposure for burning to screen

printed 3 times with ashaltum resist paint.The centre section circle was acid toned for a further 15 minutes to cut back the white tone even further before the print was made.

a simalar technique to orbital sanding with 3 microns powder prior to acid etching factory buildings.

to be continued.........

Denver Chapter of the Letterheads

Denver Chapter of the Letterheads